ABSOTEC CO., LTD.

Tel: +6621908157

Email: enquiry@absotecthailand.com

www.absotecthailand.com

| Ultrasonic Products | ||

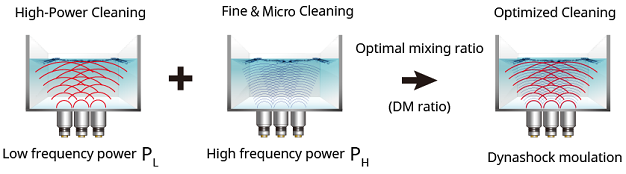

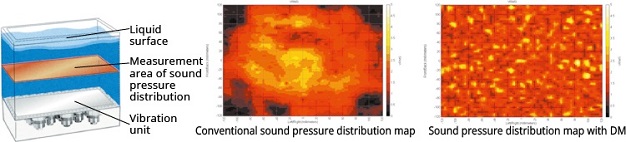

Honda Electronic Products Honda Electronics are applying our ultrasonic research to a variety of fields witdin tde industrial equipment sector. Cleaners(Ultrasonic washers), machining tools(ultrasonic welders), measuring equipment, flow meter, and so fortd, have proven tdeir use under various conditions. And new applications in tde areas of ultrasonic reactor(maturity)and power dynamics(motors) hold great promise for future success. Our Industrial Instruments Division works witd over 500 ultrasonic elemental technologies to develop and market state-of-tde-art products. And in joint research witd clients in a variety of fields, we are furtdering our goals by designing the industrial instruments of tomorrow WDX Series DYNASHOCK Modulation The technology to control the mixture ratio of two different frequency generated by the same transducers keeping the same output power. It delivers best matching ultrasonic cleaning power for the cleaning work. Lower frequency applies for hard and strong power to hard and stubborn contamination or stains. Higher frequency cleans fine and delicate structure with minimum damage to the cleaning work. The power ratio of two frequencies is named as "DM ratio". Where the low frequency power is PL and High frequency power is PH, DM ratio can be calculated as PL / PH.

|

||

Hydrophone for Ultrasonic Power Measurement Ultrasonic cleaning systems are currently used in a wide variety of industries. In all cleaning applications, it is important to control ultrasonic power to match your desire cleaning result. Excessive ultrasonic power can cause damage to your delicate product, while too little of ultrasonic power will not deliver your expected level of cleaning. Our hydrophone set provide you with the visibility of the power of your ultrasonic cleaning system. If you are interested in our Hydrophone set for ultrasonic power measurement, please do not hesitate to contact us for more detail

PPB Megasonics Products Since 1996, ppb has been the leader in providing solutions to your Ultrasonic and Megasonic cleaning efficiency concerns. With ever decreasing dimensions or need for quality assurance, the understanding and analysis of your cleaners has never been more critical. Our advanced line of cavitation metrology instruments have been proven to increase yield by accurately measuring the energy and frequency in Ultrasonic and Megasonic cleaning baths, nozzle streams and films, and cell disruptors and homegenizers Our digital hand-held meters allow users to map the in-situ energy distribution, establish tank-to-tank uniformity, and identify de-bonded or failed transducers. This is accomplished through our advance sensor and signal processing design, which captures the cavitation implosion and the driving acoustic signatures. Our probes provide an accurate and repeatable measure that incorporates such solution variables as temperature, vapor pressure, surface tension, and flow rate. Continuos monitoring is also possible with our Monitoring-Transmitter. NIST Traceable Calibration available. Download Brochure Literature Cavitation in Ultrasonic Cleaning and Cell Disruption by Lawrence Azar It is important to quantify the cavitation energy in all applications ranging from ultrasonic cleaners to cell disruptors. A cavitation meter measures the energy intensity and frequency within ultrasonic and megasonic cleaners, including probes with side-mounted sensors that can be placed within the megasonic jet streams and single wafer cleaners, as well as those resembling a beaker to quantify the energy emanating from the ultrasonic horns used for cell disruption and homogenizing. Best Practice Understanding and Evaluating Ultrasonic and Megasonic Cleaners by Lawrence Azar

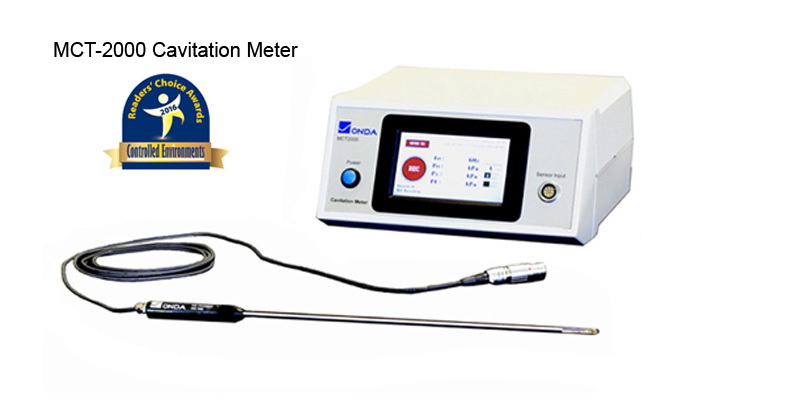

ONDASONICSOnda Corporation was originally founded as Intec Research, an R&D firm focused on developing ultrasonic technologies for clients. Much of the creativity drew on the company’s experience in medical ultrasound. Onda and National Physical Laboratory (NPL) partners to introduce the CaviMeterTM, the first commercially available instrument that quantifies the level of cavitation and direct field pressure. The MCT-2000 combines the power of a high speed digitizer, spectrum analyzer, and advanced microprocessor to produce an acoustic pressure spectrum. Different components in the spectrum are analyzed to quantify the fundamental frequency and pressure from the direct field, stable cavitation, and transient cavitation. Specifically, the pressure within the fundamental frequency peak represent the direct field pressure from the sound wave. The harmonics, sub-harmonics, and ultra-harmonics represent the stable cavitation, or the cavities that oscillate in size and dimension. Finally, the broadband white noise in the spectrum represent the transient cavitation, or the cavities that implode and collapse.

Absotec Article Achieving perfect uniformity within a bath has been elusive and assuring one is operating between effective levels is critical. Using the cavitation meter as a process control tool will improve both the yield and throughput of the cleaning operations. Comparison the cavitation meter and hydrophone by Tewarit Seemakan The cavitation meter then outputs the RMS of the cavitation energy intensity (units of watts per square inch) and the frequency of the ultrasound. These meters are not hydrophones, which typically filter out the higher frequency cavitation signatures and inherently spatially average compression and rarefaction resulting in misleading data. The cavitation signature is superimposed on the acoustic measure, but has no spatial average component. The acoustic signature is removed, compression and rarefaction, leaving behind only the cavitation implosion forces. The Study of the Performance between Hydrophone and Cavitation meter (PPB) by Nunthawun Kritsananukoon Hydrophone measure the intensitiy of ultrasonic sound from transducer. Ultrasound pressure increase when hydrophone move closer to the transducer. PPB give different result by given the highest cavitation energy at the optimum point. At the optimum point is the location that all ultrasonic wave synchronize from all transducer at the highest amplitude.

|

Products Highlight |

||

|

ONDASONIC MCT-2000

Onda introduces an award-winning next generation cavitation meter, the MCT-2000. It is based on the same principles as the CaviMeterTM, only it features a touchscreen meter which detects acoustic emissions with a calibrated hydrophone to quantify the absolute pressure from the direct field, stable cavitation, and transient cavitation.Measure the Cavitation Performance

HONDA ELECTRONICS ULTRASONIC MICROSCOPE AMS-50SI

Ultrasonic microscope, AMS-50SI uses high frequency ultrasonic wave to observe microscopic construction of biological tissues. It observes not only construction of the tissue, but also elasticity. The difference of elasticity is shown in color and it gives very good identification. The newly developed "Acoustic Impedance Mode" realized non-sliced tissue observation. "Sound Speed Mode" observation with sliced tissue is also supported.

PPB Sonicator Energy Meter (0-500kHz)

The cavitation meter has proven to be an invaluable

metrology tool to quantify the energy within the

ultrasonic and megasonic cleaners and those emanating

from ultrasonic horns. Using the cavitation meter PPB Ultrasonic Energy Meter (0-500kHz)

The Ultrasonic Energy Meters (0 to 500 kHz) are precise instruments for measuring ultrasonic and cavitation energy density, as well as the ultrasonic frequency. The systems measure energy density at a given point in time and space in a single fixed direction in the tank. The ultrasonic meters are simple and easy to use yet contains sophisticated electronics for data storage, retrieval and analysis. Readings are processed 1.5 times per second for fast accurate display on the front panel LCD. In "auto mode" the unit will gather statistical parameters including average, standard deviation, minimum and maximum readings.

RESON HYDROPHONE Ultrasonic measurement 0-150kHz

|

||

Copyright 2025 Absotec Co., Ltd. All rights reserved.