ABSOTEC CO., LTD.

Tel: +6621908157

Email: enquiry@absotecthailand.com

www.absotecthailand.com

Welcome to Absotec Scanning Electron Microscope Service Laboratory

|

Absotec found in 2000 in the LED business. We design and manufacturing of high efficiency LED with automation system. Our business starting from Malaysia and expand to Thailand in 2007. In 2007, we set our positioning in as the leading in Particle Anaysis by SEM/EDS technology in Thailand. Our produtct portfolio expand from this strategy to the most advance SEM/EDS/EBSD and uXRF. Thank you to all our partner and key account customers that confidence in us. Our skill bring us to most important attention in HDD and Forensics. Absotec becomes the leader of Particle Analysis by SEM/EDS today. Nov 1st 2018, Absotec would like to announce the opening the SEM and MicroXRF Service Laboratory. Our SEM is the most advance to support the automate particle analysis. We can support Gun Shot Residue analysis for forensics application, Mineral analysis, and all other particle analysis application. We also have M4 Tornado which is the automate elemental mapping for large sample, wet sample, rough sample, and non-conductive sample without any sample preparation. This bring us to the complete line from macro to micro analysis. HIGH TECH ANALYTICAL INSTRUMENTS

1) Scanning Electron Microscope (SEM): TESCAN VEGA3 LaB6 LM 2.0nm at 30kV 2) Energy Dispersive X-Ray Spectrometer (EDS): Oxford Instruments XMax80 Aztec Resolution 127ev 80mm2 3) High Vacuum Coater: SAFEMATC CCU-010 with Thin film thickness monitoring, <2x10-6 mbar and able to sputter Metal, Carbon, and ITO

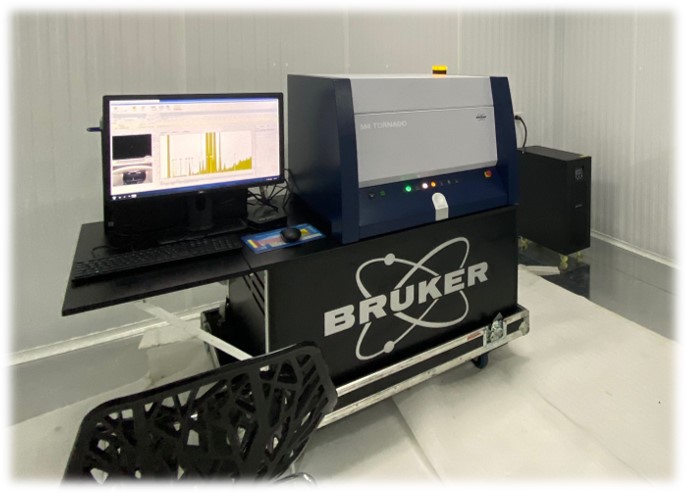

4) MicroXRF Spectrometer:- Bruker M4 Tornado spot size 20um / Large area elemental analysis, Wet sample, Rough sample, Non-conductive sample without coating SERVICE CHARGES Minimum charge is 1hr. 15mins over hour will be count as 1hr

Conditions:

Additional Service:

|

New Event

June 9-12, 2025 The 42st International Conference of the Microscopy Society of Thailand (MST42)

at Laguna Grand Hotel, Hatyai, Songkla, Thailand

New Product

.jpg)

CDS-020 Compac Drying System

World First! Automated Dehydrating and Critical Point Drying in One System

Fully automated hands off process without necessity of monitoring. Start a process in the evening get your dried specimen in the morning. Greater process reliability and traceability due recipes and process tracking. Dehydration and critical point drying in ONE piece of equipment. Less space required in the laboratory. Samples up to the size of 30mm. Less sample handling. No use of refrigerants.

![]()

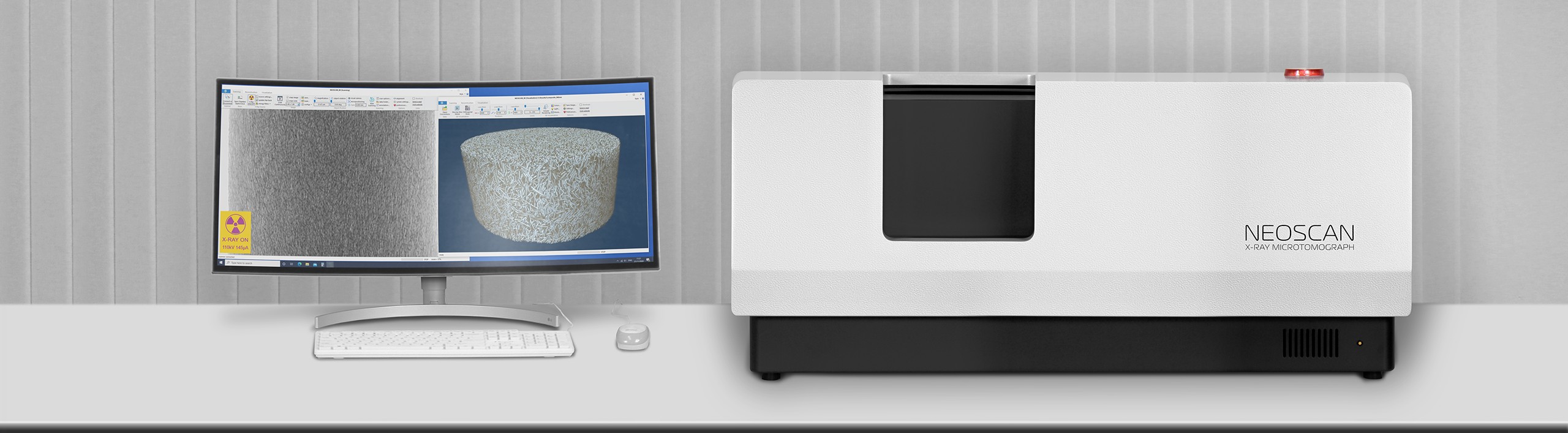

NEOSCAN N80 Scientific grade, high-resolution micro-CT scanner

Low contrast resolution 2 um

15 x better 3D resolution compared to microCT with 5um source spot size

X-ray source up to 110 kV

Covering a wide range of applications like geology, composites, bone, dental, electronics,...

Fits objects up to 100mm diameter and 200mm length

Generous sample size

Delong Instruments has developed the world’s first table-top TEM and specializes in low electron energy

Absotec becomes the distributor of Delong Instruments in Thailand. This is so great opportunity to promote the most advance Low Voltage TEM (LVEM).

Delong Instruments Company is based in Brno, Czech Republic – the world capital of electron microscopy. Delong Instruments has more than 25 years of experience in the field of transmission electron microscopy (TEM). The company is also developing advanced electron-optical instruments, providing engineering design services and manufacturing precision parts and vacuum technology. Its main objective is to make electron microscopes more accessible and practical. That is why Delong Instruments puts extra emphasis on keeping microscopes innovative, compact, and easy to install, maintain and operate. Delong Instruments has developed the world’s first table-top TEM and specializes in low electron energy, which helps their microscopes to achieve high contrast of light elements and low radiation load, thus extending the range of observation methods. For more information, please visit www.delong.cz

LVEM 25E Compact Transmission Electron Microscope

The LVEM 25E is the All in One compact transmission electron microscope. It is versatile in that it combines 3 imaging modes with 2 analytical modes into one self-contained instrument. This advanced design combined with an impressive resolving power makes the LVEM 25E an exceptional partner for all your nanoscale imaging requirements. To request a detailed, no obligations quote today, simply click the button below and we will be happy to provide one for you.

More detail

MountainsMap®

Surface metrology and analysis software for profilometers (2D contact or optical profilometers, 3D areal optical or contact stylus profilometers, confocal microscopes, focus variation microscopes, white-light interferometers and light microscopes).

Visualize and analyze profile and surface data and perform a multitude of studies including surface roughness using an advanced set of professional tools.

MountainsSEM®

MountainsSEM® is a visualization and image analysis software designed specifically for scanning electron microscopes (SEM). MountainsSEM® is compatible with any brand or model of SEM.

Perform 3D reconstruction, semi-automatic image colorization, advanced 2D particle analysis and much more all in an intuitive interface.

MountainsSPIP®

Image processing and analysis software for scanning probe microscopes (SPM) including atomic force microscopes (AFM). Includes tools for particle analysis, colocalization (correlative analysis), force spectroscopy and powerful statistical tools. Includes tools previously contained in SPIP™ image analysis software.

MountainsSpectral®

MountainsSpectral® is a comprehensive solution for image and data processing for use with spectroscopic techniques including Raman, TERS, FT-IR, nanoIR, fluorescence, photoluminescence, cathodoluminescence, EDX/EDS and XRF.

MountainsImage®

MountainsImage® is a comprehensive image analysis solution for processing B&W and color images obtained using light microscopy and other imaging systems.

![]()

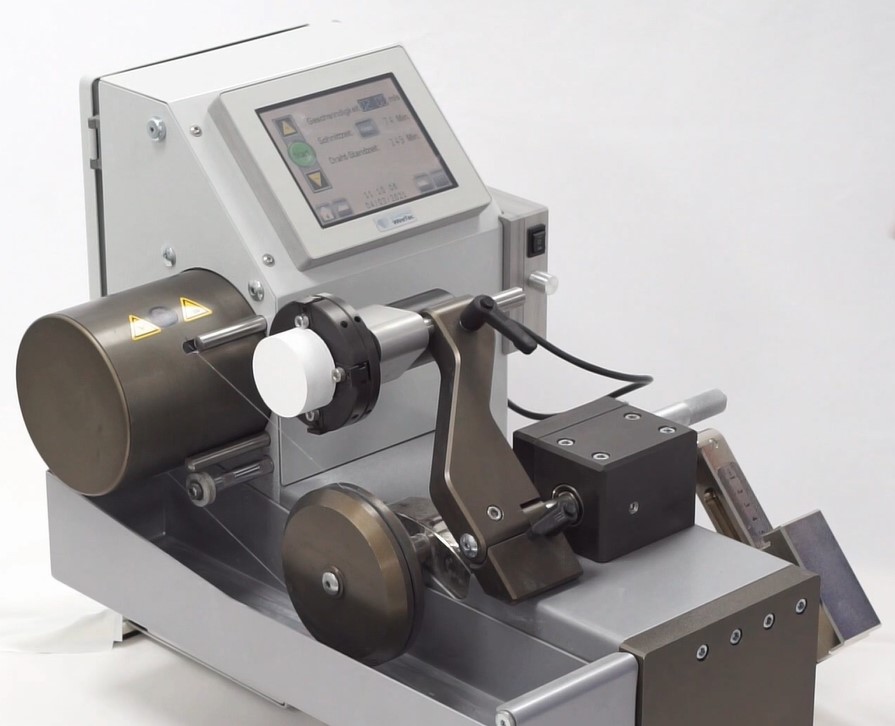

Diamond WireTec

Highest Precision Diamond Wire Cut for Laboratory

The diamond wire saw type DWS.100 is a table saw in horizontal design so that the smallest cut-offs can be observed with the naked eye or also by means of an attached microscope. Minimum roughness and evenness with Rotary drive.

The maximum workpiece cutting area is 90 x 90 mm and the recommended diamond wire thickness is 0.08 to 0.35 mm. The continuously adjustable wire speed goes from 0 to 4 m/s. To ensure a constant cutting pressure, the feed is done by gravity. Workpieces can be cut both wet and dry.

More detail

Copyright 2023 Absotec Co., Ltd. All rights reserved.